Bridge Preservation and Management

English translations of related MLIT documents for periodic inspection of road bridgesThe Ministerial Ordinance of the Japanese Ministry of Land, Infrastructure, Transport and Tourism (MLIT) requires road administrations to conduct statutory inspections of road bridges. It also provides technical guidance and standards for bridge inspection. The Bridge and Structures Division of the National Institute of Land and Infrastructure Management studies the condition of road bridges in Japan. It closely supports the MLIT headquarters in establishing and improving the standards of preservation, maintenance, and inspection practices.

The Bridge and Structures Division also conducts international cooperative studies on bridge design, construction, and management with various institutions. To share information on national road bridge inspection standards with such colleagues, the Bridge and Structures Division prepares preliminary English translations of road bridge inspection standards. Any translation, including the title of the documents, is not official and has not yet been proofread or corrected by a native English speaker or a legal translation expert; this translation may be revised in the future. Only the original Japanese texts of the documents have legal effect, and the translations are to be used only as reference materials to aid in the understanding of the national standards summary. The Bridge and Structures Division is not responsible for the accuracy and reliability of the translation. In addition, please note that each road administration sets its standards to meet legal requirements and to follow the national standards, which often add their original data recording rules, for example.

- Periodic inspection guidelines for highway bridges

(Technical advice under the Local Autonomy Act) - Commentary to the Technical Advice to Road Administrators and Practical Standards

- Guideline for recording basic data (Road Bridges) 2024 version

Periodic inspection guidelines for highway bridges

(Technical advice under the Local Autonomy Act)

March 2024

Road Bureau, Ministry of Land, Infrastructure, Transport and Tourism

(Technical advice under the Local Autonomy Act)

1. Scope

2. Frequency of periodic inspections

3. System of the periodic inspections

4. Understanding the condition

5. Determination of integrity diagnosis classification

6. Records

- Scope

- Frequency of periodic inspections

- System of the periodic inspections

- Identifying the condition

- Determination of integrity diagnosis classification

- Records

- Bridge name

- Route name

- Location

- Location coordinates (latitude and longitude)

- Facility ID

- Administrator

- Crossing objects

- Availability of alternate routes

- Type of road (whether it is a motorway or a general road)

- Emergency transportation road

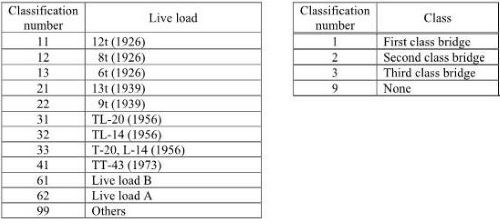

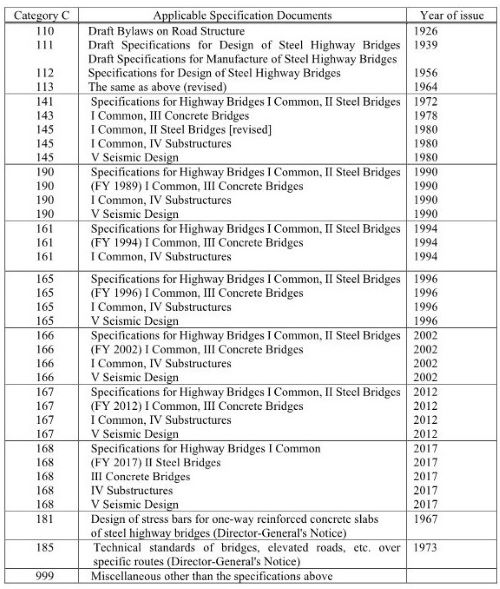

- Bridge specification

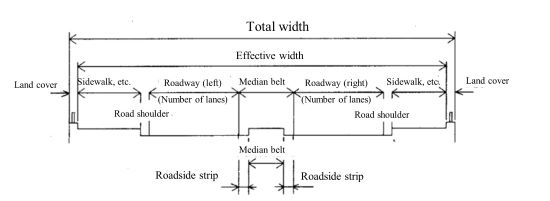

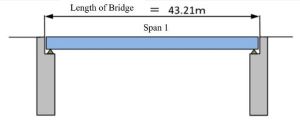

- Bridge specifications (year built, bridge length, width, bridge type)

- Integrity diagnosis classification as per the ministry notification

- Inspectors (persons with the knowledge and skills to perform periodic inspections)

These guidelines apply to roads under the Road Act with bridges that are 2.0 meters or longer.

The inspection interval is generally set at once every five years. If necessary, consideration should be given to conducting these inspections at intervals shorter than five years.

Periodic inspections shall be performed by a team of individuals who possess the necessary knowledge and skills to determine the integrity diagnosis classification appropriately.

The periodic inspection shall use appropriate methods to obtain information on the condition of the highway bridge at the time of inspection that is considered necessary to determine the integrity diagnosis classification properly. At this time, gather information deemed necessary for evaluating the load carrying performance, durability performance, and additional performance to meet functional or safety objectives at the point of periodic inspection through close visual inspection or other methods that can provide an equivalent evaluation to a close visual inspection.

(1)When determining the integrity diagnosis classification, consider the surrounding circumstances of the highway bridge and anticipate the situations it may encounter until the next periodic inspection, estimate the potential state of the facility, and consider possible disruptions to road functions or risks to third parties, based on which, and from the perspective of efficient maintenance and repair, review the measures that should be taken by the next periodic inspection.

(2)The determination of the integrity diagnosis classification should reflect the nature of the measures to be taken, such as periodic or continuous monitoring, maintenance and repair/reinforcement, removal, traffic control and road closures, etc.

(3) The periodic inspection shall determine the integrity diagnosis classification for each facility. At this time, it is desirable to consider the results of examining what function and safety states are likely to occur for each of the superstructure, substructure, and connection between superstructure and substructure for the anticipated situation, as specified in the “Specifications for Highway Bridges (2017).”

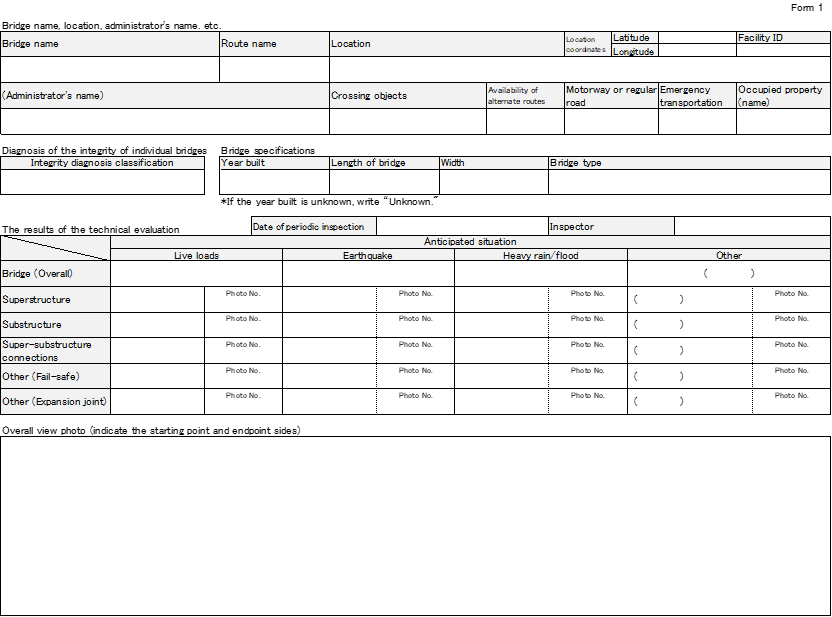

(1)The results of periodic inspections should be recorded in a form that can be utilized, based on the following information considered necessary for appropriate maintenance and management, including responses in the event of in-service damage.

(2)It is recommended that the technical considerations related to the measures evaluated in Item 5, including the structural integrity of the superstructure, substructure, and their connections, be documented in response to anticipated conditions. This should include the need for preventive maintenance and the potential for third-party damage.

Commentary to the Technical Advice to Road Administrators and Practical Standards

March 2024

Road Bureau, Ministry of Land, Infrastructure, Transport and Tourism

March 2024

Road Bureau, Ministry of Land, Infrastructure, Transport and Tourism

0. Preface

1. Scope

2. Frequency of periodic inspections

3. System of the periodic inspection system

4. Understanding the condition of each bridge

5. Integrity diagnosis classifications

6. Records

7. Appendix: Forms

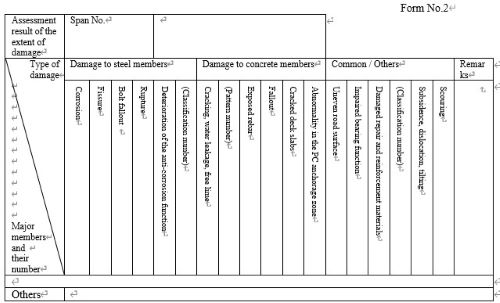

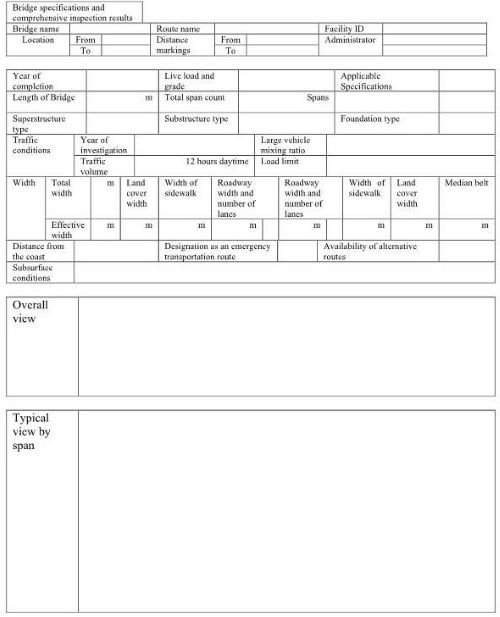

8. Guide to recording in Form 1

9. Guide to recording in Form 2

10.Guide to recording in Form 3

Preface

Based on Article 245-4, Paragraph 1 of the Local Autonomy Act or Article 48, Paragraph 1 of the Act on Special Measures concerning Road Construction and Improvement, this technical advice is provided to local governments and other relevant entities to indicate matters deemed appropriate by the national government. This advice represents the minimum necessary to achieve the objectives of the national laws established by the government. These guidelines, in line with the purpose of such technical advice, aim to indicate the minimum desirable actions that road administrators should undertake to achieve the objectives of periodic inspections conducted under Article 4-5-6 of the Order for Enforcement of the Road Act. Additionally, they include explanatory notes on matters that can serve as references for implementing these actions.

- Scope

- Frequency of periodic inspections

- System of the periodic inspection system

- Relevant qualifications or considerable work experience in road bridges

- Considerable expertise in the design, construction, and management of road bridges

- Considerable skills and work experience in periodic inspections of road bridges

- Understanding the condition of each bridge

- Integrity diagnosis classifications

- I: Routine and scheduled maintenance are implemented, but no further preventive measures or monitoring are required until the next periodic inspection.

- II: It is timely to implement preventive and preservation measures, mainly to ensure longevity and durability, and actions are desirable before the next periodic inspection.

- III: Measures need to be taken before the next periodic inspection to ensure the bridge's structural safety and prevent harm to third parties.

- IV: Measures must be taken urgently to ensure the bridge safety and prevent harm to bridge users and third parties.

- where and what kind of distress exists, specifically,

- what the possible bridge load-carrying state of the road bridge would be in response to the situations it may encounter until the next periodic inspection

- the potential risk of disruptions to traffic functionality and harm to third parties if the bridge reached such a state under an anticipated situation, in comparison to the road administrator's perspective on the expected role of the bridge

- timely and efficient implementation of preventive maintenance.

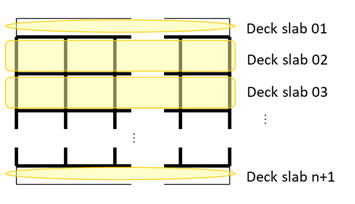

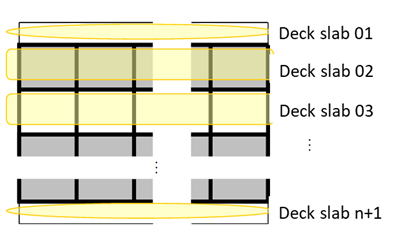

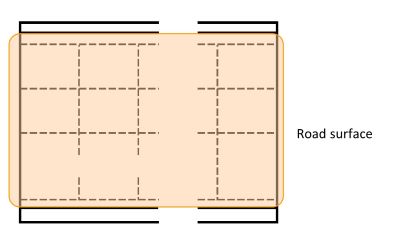

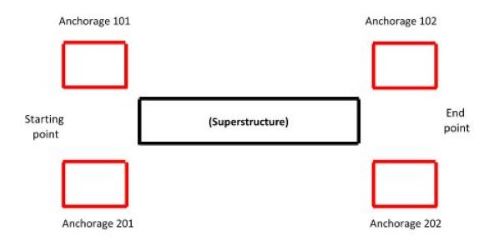

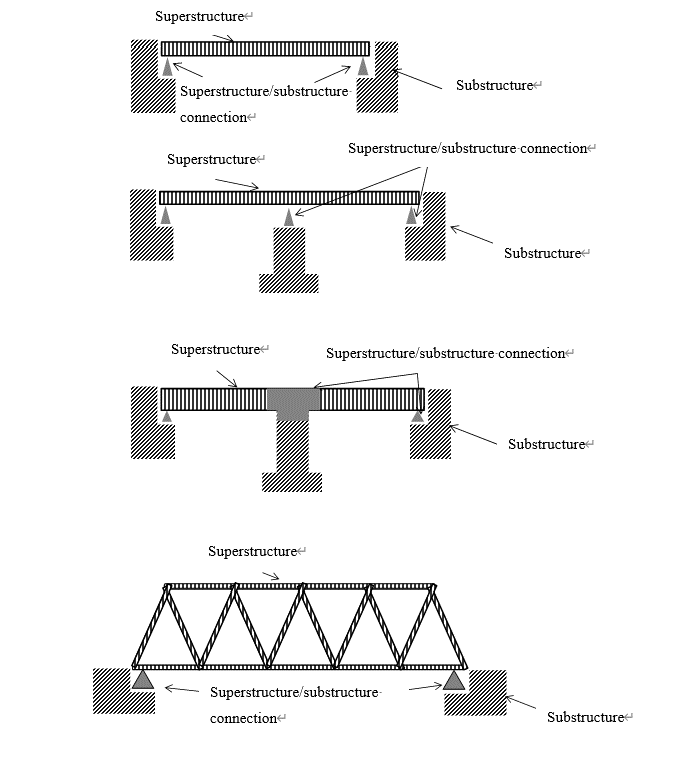

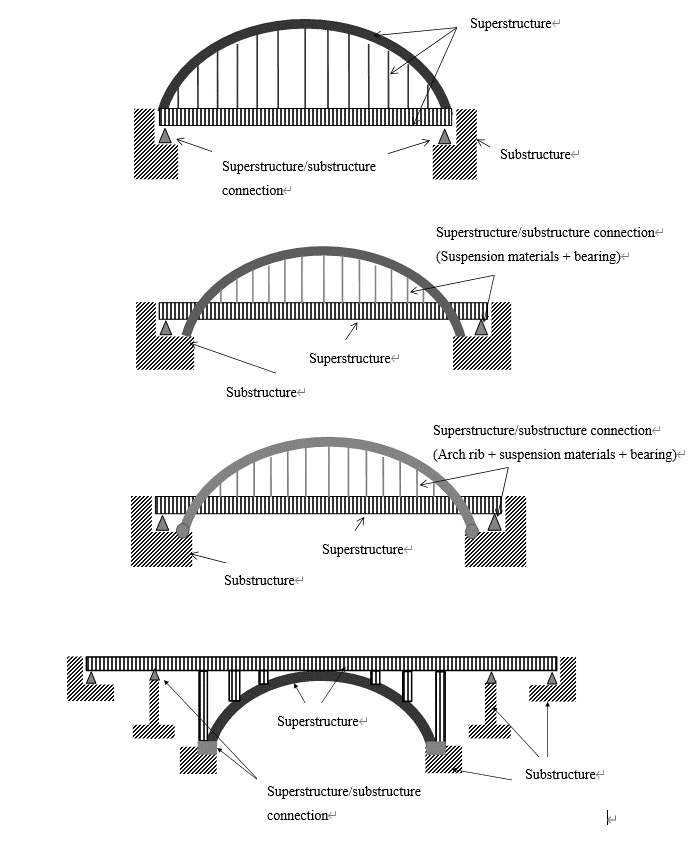

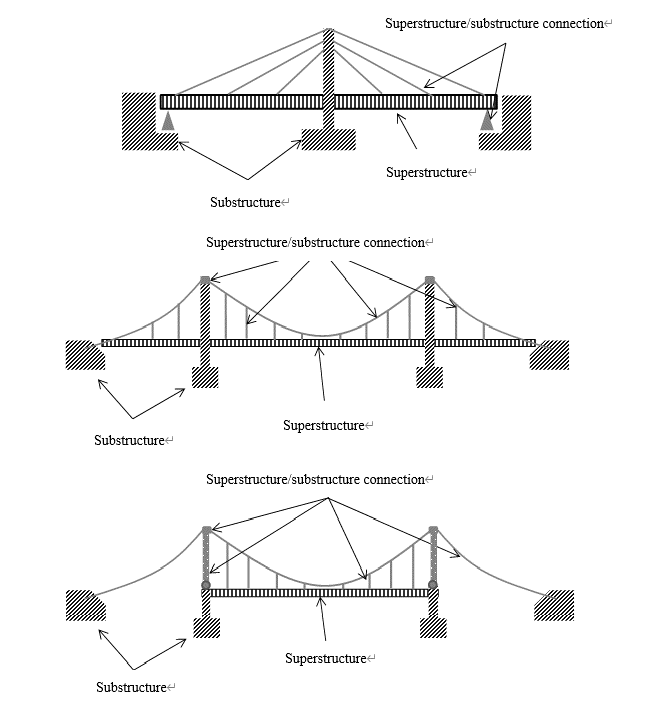

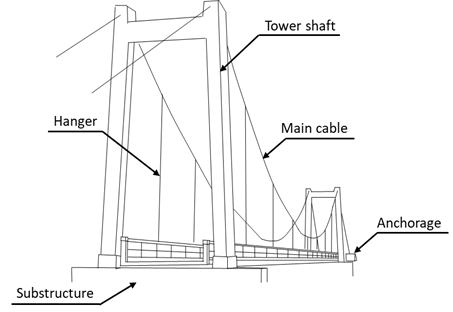

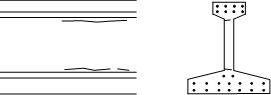

- Superstructure is the structural components that play a role of part of the road thereof and directly support traffic loads of vehicles and pedestrians.

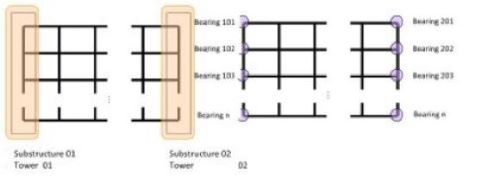

- Substructure is the structural component that plays a role in holding the super-substructure connection in an appropriate position.

- Super-substructure connection is the structural component that plays the role of the support points for the superstructure and transmits its load effects to the substructure.

- A: The likelihood of damage or irregularity to the dysfunction of the bridge is low.

- B: Although the likelihood of a critical state is low, there is a possibility of resulting in some damage or irregularity to dysfunction the bridge.

- C: There is a possibility that the bridge falls into a critical state.

- Records

- Bridge name

- Route name

- Location

- Installation location (latitude and longitude)

- Facility ID

- Administrator

- Subgrade conditions

- Availability of alternate routes

- Type of road (whether it is a motorway or a general road)

- Emergency transportation road

- Occupied properties

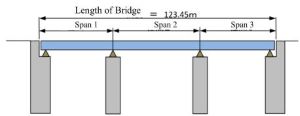

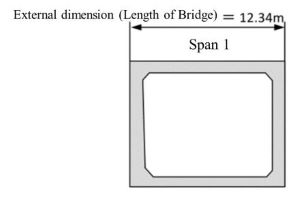

- Bridge specifications (year built, length of bridge, width, bridge type)

- Integrity diagnosis classification as per the Ministry notice

- Date of periodic inspection (the final day on which the condition assessment was conducted)

- Periodic inspectors (persons with the knowledge and skills to perform periodic inspections)

- Results of technical evaluations

- A: The likelihood of damage or irregularity to the dysfunction of the bridge is low.

- B: Although the likelihood of a critical state is low, there is a possibility of resulting in some damage or irregularity to dysfunction the bridge.

- C: There is a possibility that the bridge falls into a critical state.

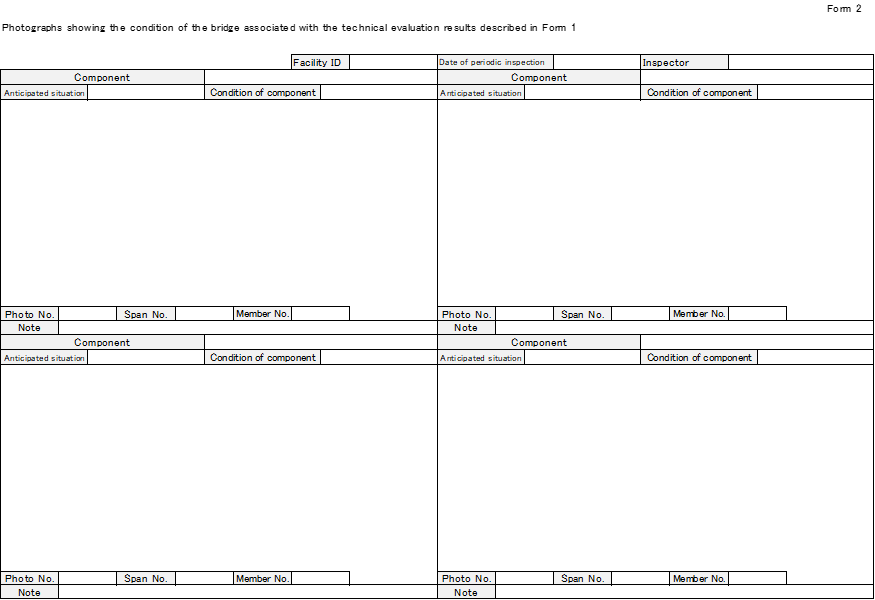

- Photo number

- Anticipated situations

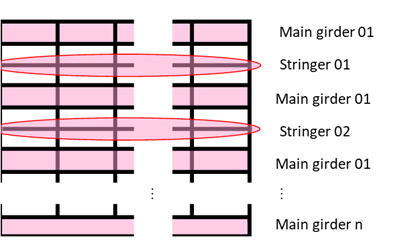

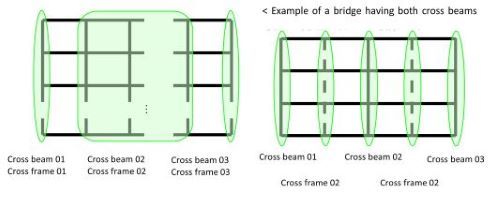

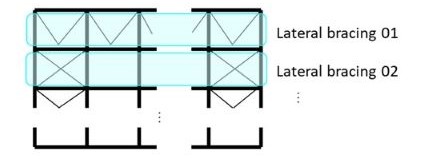

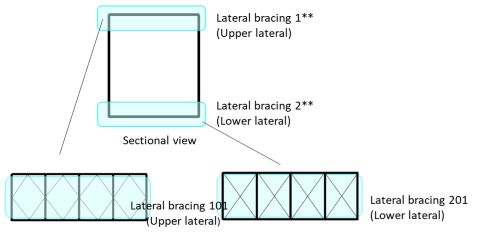

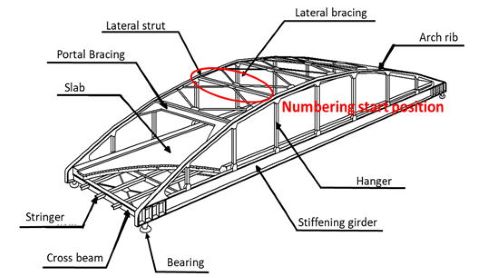

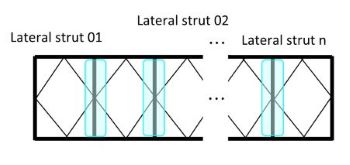

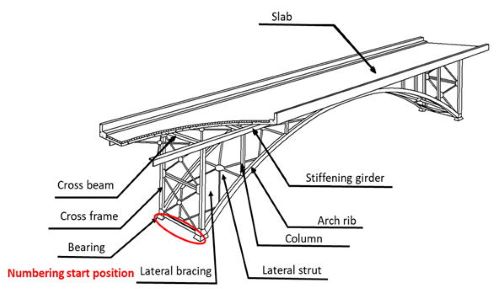

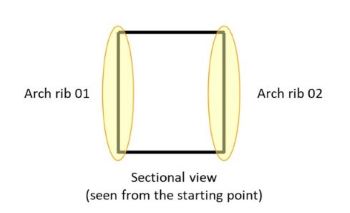

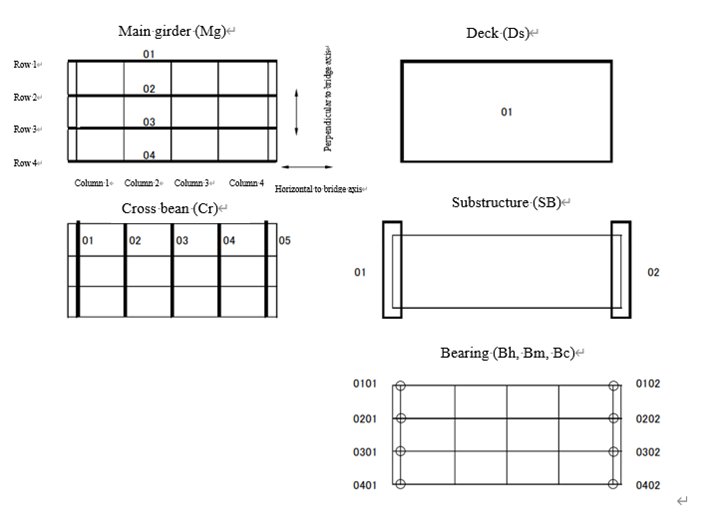

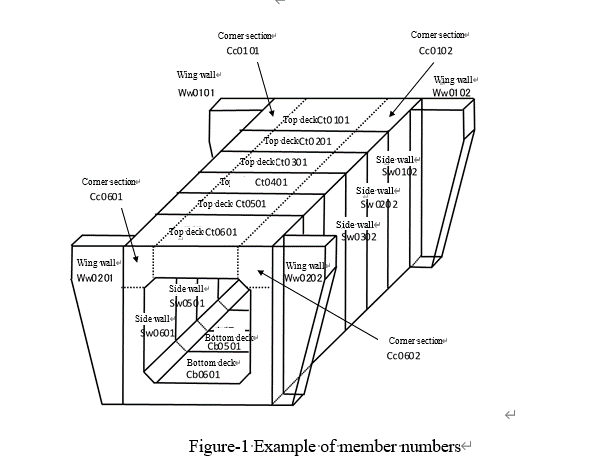

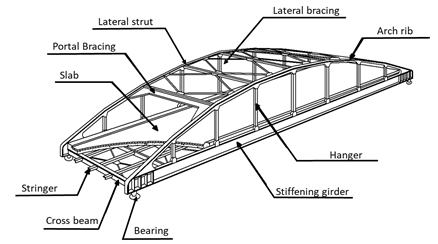

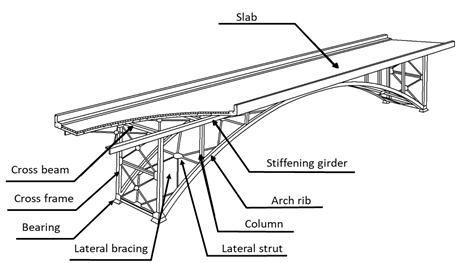

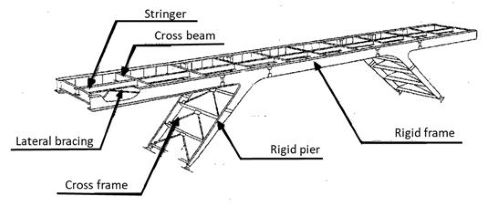

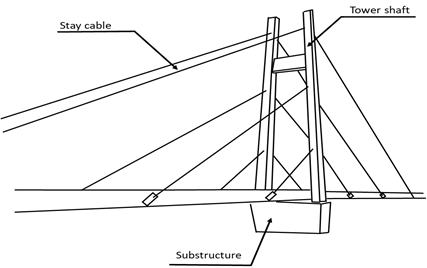

- Component configurations

- Components

- Anticipated situations

- Condition of components

- A: The likelihood of damage or irregularity to the dysfunction of the bridge is low.

- B: Although the likelihood of a critical state is low, there is a possibility of resulting in

some damage or irregularity to dysfunction the bridge. - C: There is a possibility that the bridge falls into a critical state.

- Photographs

- Remarks

- whether the function of the component is likely to be retained

- whether it is expected to lose its function,

- or none of the above.

- Functions required of components

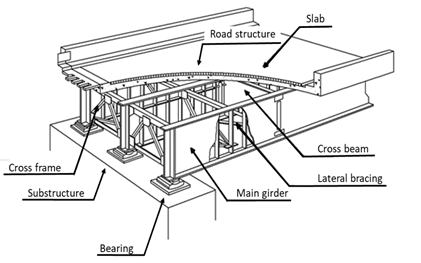

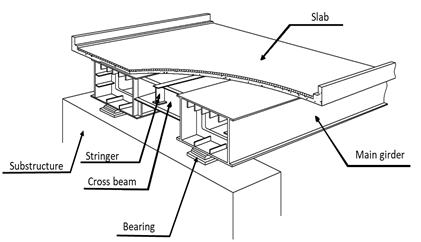

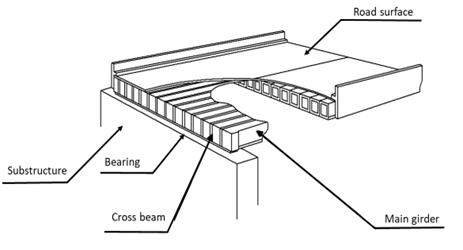

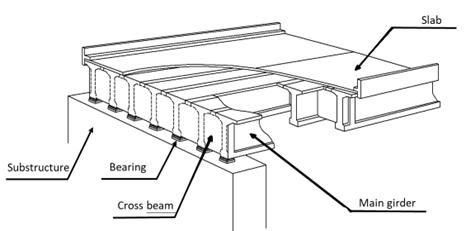

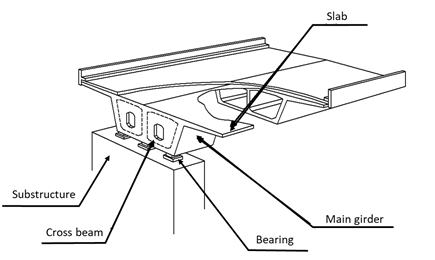

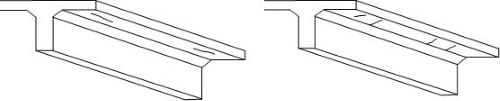

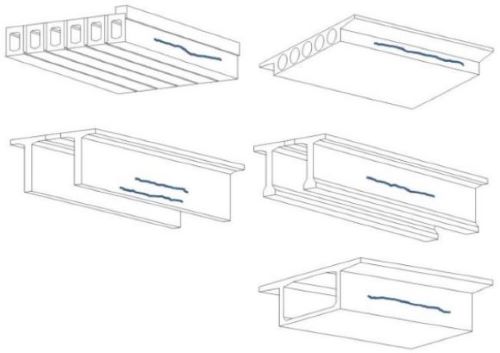

- Example: Decks and stringers often carry out this function.

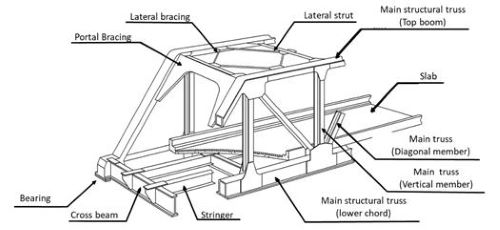

- Example: Main girders, trusses, and arches often perform this function. Decks may sometimes serve this function as part of the main girder.

- Example: Transverse girders, cross-frames, etc. maintain the cross-sectional shape of the superstructure against loads.

- Example: This function is often carried out by bearing supports. Rigid connections also serve this function when the super-substructure connections are rigidly connected.

- Example: This function is often carried out by the same parts and members as in Item iv.

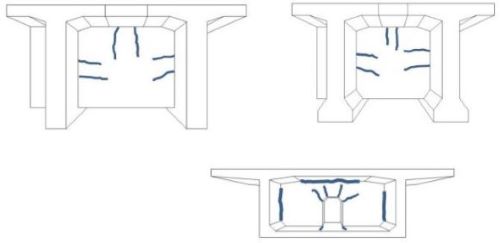

- Examples: Piers, abutments, bearing seats, and cap beams often carry out this function.

- Example: Foundations and the surrounding subsoil layers often carry out this function..

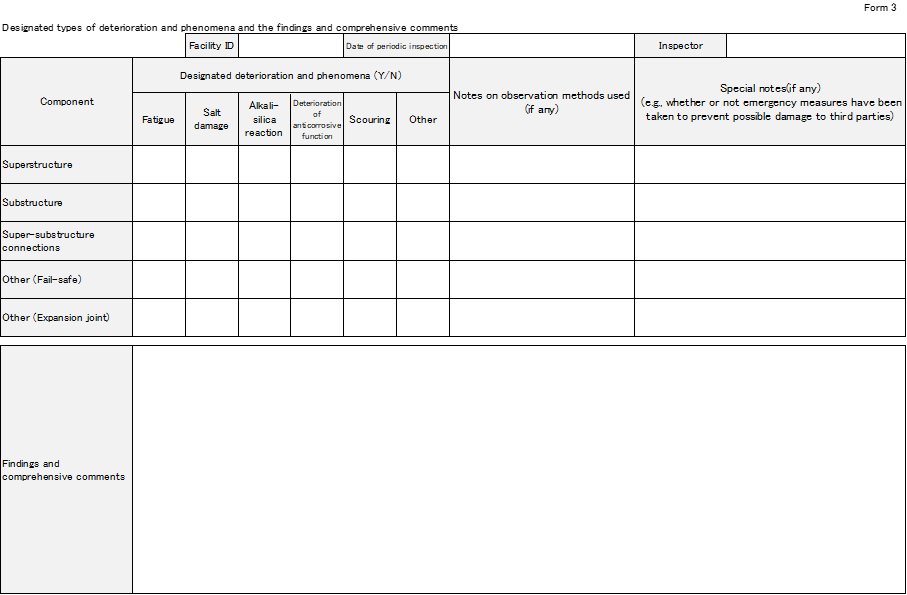

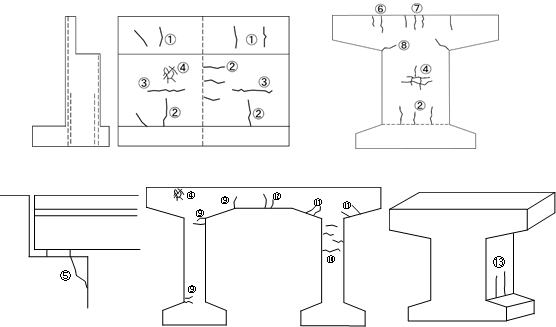

- Designated types of deterioration and phenomena

- Notes on observation methods used

- Special notes (e.g., whether emergency measures have been taken to prevent possible damage to third parties)

- Findings and comprehensive comments

- The condition identified during the inspection that serves as the basis for performance evaluation (types, locations, and characteristics of damage)

- Estimation of the cause of the damage and the potential for its progression. The condition identified during the inspection and any information referenced as the basis for the estimation

- Estimation of the structural safety of the superstructure, substructure, and connection between superstructure and substructure under the anticipated situations

- Evaluation of long-term deterioration, taking into account the condition of relevant designated types of deterioration and phenomena, from the perspectives of the necessity of preventive maintenance and the achievement of longevity

- The potential impact on road users and the likelihood of third-party damage. Additionally, if these factors are reflected in the technical evaluation of the potential conditions under anticipated situations, it is advisable to record this information clearly

- Technical opinions on the necessity of the measures considered in the determination of the integrity diagnosis classification, taking into account the technical observations on the condition of the road bridge, together with the surrounding situations

- The presence or absence of urgency for measures

- The necessity of detailed investigations or follow-up surveys, such as those on the potential

for discrepancies in performance evaluations based on the accuracy of information

obtained by the understanding of the condition - Other items that should be recorded as necessary for future measures or the next periodic inspection

- Damage

to reinforcement materials can take various forms depending on their material

and structural details. In addition,

water leakage, free lime and other defects in reinforcement materials sometimes

arise from the damage in the concrete members strengthened. Such defects shall be treated as deterioration

of the function of reinforcement materials and included in this category

"damage to repair and reinforcement materials", separately from

damage to the existing structural member.

- In Classification 3 when cracks or exposure of rebars is present in concrete jackets such damage also shall be assessed as cracks or exposure of rebar thereof

- As for Classification 4 the coating damage shall not be treated as "Deterioration of corrosion protection."

- As for Classification 5, damage to cover plates installed on steel

members shall be dealt with only in this category, not in categories such as "Deterioration

of corrosion protection" or "corrosion". On the other hand, if the existing structural member is damaged as well

due to the cover plate (damage), the damaged existing structural member

shall be separately assessed as well

These guidelines apply to periodic inspections of bridges 2.0 m or longer in length, elevated roads, etc. (hereinafter referred to as “bridges”) on roads stipulated in Article 2, Paragraph 1 of the Road Act (Act No. 180 of 1952).

Considering the purpose of periodic inspections and the fact that the Road Statistics Annual Report accounts for bridges with a length of 2.0 m or more on roads as road bridges, a periodic inspection is recommended for bridges with a bridge length of 2.0 m or longer be applied to a periodic inspection in conformity to the technical advice on bridge periodic inspection issued by Road Bureau, MLIT, in March 2024.

Additionally, it is advisable that any structure that crosses over an obstruction or a depression

and supports traffic live loads as the body of the road as a bridge defined in this guideline.

Additionally, it should be noted that even bridges with a length of less than 2.0 meters can

experience deterioration or damage that may pose concerns for road safety and third-party harm.

In principle, periodic inspections must be conducted at intervals of 60 months for each road

bridge. If necessary, periodic inspections at intervals shorter than five years should be

considered. A periodic inspection finally determines one of the integrity diagnosis classifications defined

in the notice, considering the change in bridge condition and the surrounding circumstances

until the next periodic inspection, with identifying deficiencies at each structural member,

inferring the performance of the bridge at the time of the inspection, and evaluating the relevant

maintenance and repair needs and policy from the engineering viewpoint. Depending on the installation and surrounding condition, it may be difficult to conduct a

periodic inspection at the precise five-year interval. Even in such a case, periodic inspection

must be conducted f at intervals not far exceeding five years. Depending on the integrity

conditions, the bridge state could worsen rapidly and become critical in less than five years.

Accordingly, it may also be necessary to consider conducting the periodic inspection at an

interval shorter than five years when needed. Note that road administrators must conduct daily and other inspections properly regardless of

integrity diagnosis classifications of periodic inspection, such as post-event or emergency

inspections after an accident or disaster, in addition to the mandatory periodic inspection by the

related regulations, and endeavor to maintain the proper functioning of road bridges, as

stipulated in the Road Act and related regulations. Periodic inspections shall be performed by a team of persons who possess the necessary

knowledge and skills to determine the integrity diagnosis classification appropriately. Road bridges are subjected to various ground conditions, traffic, and other surrounding

conditions, with different structural member arrangements and materials. Accordingly, the

impact of distress and damage at structural members on bridge performance and third-party risk

of harm varies bridge by bridge, even if distress of the same type and extent develops at the

same structural element type. Furthermore, the necessity and purposes of remedial measures

for each road bridge will vary depending on the socio-economic and disaster preparedness roles

of the bridge and road network, factors related to its durability, and other factors. Accordingly, in periodic inspections, each bridge shall be diagnosed into the “integrity

diagnosis classifications” defined in the ministry notification by a comprehensive assessment

that considers the anticipated situations and surrounding circumstances until the next periodic

inspection, the current condition and distress observed, ant the evaluation of the expected

performance. Therefore, actions that influence the quality of statutory inspections—such as understanding

the condition, inferring the performance and its change over time, determining the integrity

diagnosis classification, and making records to be preserved for the future—must be carried out

by persons who possess the necessary knowledge and skills to perform these tasks appropriately.

For example, satisfaction with any of the following requirements is an essential aspect of

evaluating whether the person has the necessary knowledge and skills:

Note that the required minimum technical level of understanding and evaluating the present and

foreseeable bridge conditions and performances as part of a statutory periodic inspection is

interpreted as equivalent to the level at which a person with the sufficient knowledge and skills

can infer them roughly based on the information obtained basically within their close visual

inspection. It does not necessarily require a structural analysis, precise surveying, or rigorous

understanding of the condition through advanced tests. It should be also noted that ultimately, for each bridge, the demands for the technical extent o

and methodologies for inspectors to obtain and evaluate necessary information as part of a

statutory inspection, such as inspection methods and specifications, must be authorized by road

administrators, because the information obtained in inspection is used for the road

administrators to categorize the bridge condition into one of the integrity diagnosis

classifications. The condition of each bridge shall be observed using sufficient methods for the bridge

administrator to determine the integrity diagnosis classification properly. Close-visual

inspection is the principal method of gathering information to evaluate load-carrying,

durability, and supplemental performance to fulfill functional or safety requirements.

Alternative methods can be used when obtaining equivalent reliability of the information

compared to those obtained by a close visual inspection to evaluate those performances. Periodic inspections require the determination of the “integrity diagnosis classifications” for

each road bridge as defined in the ministry notification, based on the technical diagnosis from

a person with the necessary knowledge and skills who inspects the bridge through the essential

inspection method of close visual observation and evaluate its current condition and various

other information and given conditions.

The bridge condition is one of the most essential pieces of information for determining the

“integrity diagnosis classification”, and the ministerial ordinance stipulates that a person with

the necessary knowledge and skills for bridge inspection and diagnosis shall acquire the

information on the bridge condition through close visual inspection. The ministerial

ordinance presumes that close visual inspections involve approaching the subjects to be

examined to evaluate the condition and structural member performances close enough to

observe the details of their external distress and irregularity and, if necessary, to perform tactile

examinations or sounding or hammering. However, the ministerial ordinance does not

entirely prohibit alternative inspection methods. It acknowledges that there can be cases

where alternative methods if used with care and expertise, can provide a technical diagnosis

with equal reliability to determine the “integrity diagnosis classification” compared to that via

a close visual inspection.

In addition, there may be cases where the information obtained visually alone is considered

clearly insufficient to determine the integrity diagnosis classifications as defined in the ministry

the bridge integrity diagnosis classification also depends on the long-term service plan of the

subject bridge and the foreseeable changes in the structural condition, surrounding and location

environment, traffic, and other situations that may lead to a change in the evaluation result of

the load-carrying, durability, and supplemental performances, in addition to the present bridge

condition evaluated via a close visual inspection.

Accordingly, when evaluating the condition and performance levels of the entire bridge, how

close the inspector approaches each structural part in the close-visual inspection and the need

to use inspection methods other than close-visual inspection, such as touching, sounding, and

hammering, depends on the types and characteristics of the entire structure or structural details,

the condition of neighboring structural portions and members, the anticipated causes and types

of deterioration, environmental conditions, and surrounding conditions. Accordingly, the

criteria to validate the enough distance in close-visual inspection or the need for other inspection

methods cannot be uniformly set out for all bridges and structural members. The inspector is

responsible for considering and proposing them, and the road administrator will make the final

judgment of their relevancy at their discretion.

In a periodic inspection of bridges, the physical condition of the structure is assessed in terms

of whether the bridge can be used appropriately under normal traffic conditions or those

anticipated by the road administrator, focusing mainly on the traffic function and structural

safety, primarily focusing on the load carrying performance, against the situations anticipated

before the condition is assessed again in the next periodic inspection. The assessment of safety,

the evaluation of age-related deterioration from the viewpoint of the need for preventive

maintenance and the realization of the longevity of road bridges, and the assessment of the

possibility of damage to road users and third parties due to falling parts or members from the

body of a bridge or its appendages, etc., are made as technical opinions at the time of the

periodic inspection based on available information. In addition, these technical opinions will

also be considered in deliberating the measures that are deemed desirable to be taken before the

next periodic inspection. Then, based on these as the primary basis, the road administrator

will judge and decide which of the “integrity diagnosis classifications” defined in the notice

corresponds to the final decision made by the road administrator on measures for the subject at

that time.

In other words, periodic inspections are required to obtain information on the condition of

deterioration and anticipated factors of deterioration that are considered necessary to perform

these studies and assessments properly. It can be interpreted that the information obtained by a

person with sufficient knowledge and skills through close visual inspection is considered the

standard for such information.

(1) Statutory periodic inspections must determine a relevant integrity diagnosis classification

from Table 5.1, following the “Notice on the Classifications of the Results of Integrity

Diagnosis of Tunnels, etc.”. (2) When determining the integrity diagnosis classification, infer the anticipated load

-carrying function state of the facility under situations it may encounter and assess the

impact of the anticipated bridge state on the likelihood and possible extent of service

impairment or damage to people under the bridge. In addition, consider the chance of

implementing effective maintenance and repair. Then, finally, sum them up and review

the desirable remedial work policy of the bridge for the next periodic inspection.

(3) The desirable remedial work policy, which is reflected in the integrity diagnosis

clarification, basically comprises measures covering periodic or continuous monitoring,

maintenance, repair/reinforcement, demolition, traffic restriction, and road closures.

(4) Although the periodic inspection for each bridge requires determining the integrity

diagnosis classification for each facility unit (i.e., as a whole bridge system), it is

reasonable to simultaneously evaluate what conditions the superstructure, substructure,

and connection between superstructure and substructure are likely to be individually for

the same anticipated situation as those considered in evaluating the facility (the whole

bridge). Note that the definitions of superstructure, substructure, and super-substructure

connection are specified in the Specifications for Highway Bridges, 2017.

(1) The basic relationship between the integrity diagnosis classifications and anticipated

remedial / countermeasure actions is as follows.

It may be desirable to implement temporary measures during periodic inspections to remove

the risk to road users and third parties due to falling, such as flaking, detachment, corrosion

fragments, and paint flakes

Suppose any such temporary measures were taken at the time of inspection. In that case,

evaluating the possible bridge performance under the anticipated situations until the next

inspection and deciding the integrity diagnosis classification should be based on a technical

assessment of the bridge condition after the temporary measures were implemented.

(2) The decree requires that inspections consider the structure of the road, traffic conditions,

maintenance or repair conditions, the terrain, geology, weather conditions of the area where the

road is located, and other relevant factors. It also requires considering the need for efficient

maintenance and repair of the road. The decree also requires diagnosing the integrity of a

structure to account for the possibility of significant road structure malfunction or interference

with traffic.

In other words, in statutory inspections, considering the desirable measures to maintain the

bridge condition until the next statutory periodic inspection and declaring a relevant "integrity

diagnosis classification" as defined in the ministry notification must be based on the road

administrator's perspective on the expected role of the road bridge as part of the road section.

Plus, reviewing desirable remedial measures involves a comprehensive understanding of the

bridge condition, factoring in the following aspects

(3) When considering the preservation and remedial work polity for bridges, periodic or

continuous monitoring, maintenance, repair, or reinforcement measures are reviewed to

maintain or recover the bridge load-carrying functionality, durability, and demolition. In

addition, traffic restrictions or closures should be considered when urgent actions are needed

but cannot be taken.

The technical evaluation result of expected bridge performance should be needed for road

administrators to review the measures that deserve to be taken and determine integrity

diagnosis classifications for individual bridges. However, it is also essential for road

administrators to recall the fact that periodic inspection is based on close visual observations

Taking this fact into consideration, road administrators need to scrutinize not only the necessity

and policy of measures but also the need for further investigations to make the measures

reasonable and appropriate.

In addition to the technical evaluation result of the bridge, the role of the bridge on the road

network from the viewpoint of social and economic activities and its mid and long-term

maintenance strategy should be comprehensively incorporated in the decision-making process

for the measures to be taken. Finally, as a result of these considerations, the integrity

diagnosis classification must be decided, referring to the definitions of each classification in

the ministry notification of the integrity diagnosis classifications.

When the maintenance and remedial work policy for the bridge is reconsidered as a result of

obtaining additional information from detailed investigations or changing the bridge condition

due to events like earthquakes after the periodic inspection, prompt reassessing the integrity

diagnosis classification until the next inspection and updating the bridge integrity classification

record is recommended.

Structural monitoring can be counted as one of the optional measures to be taken while waiting

to implement the desirable remedial works and countermeasures in response to the inspection

result. It is implemented to track the change in the state of distress such that the result can be

a trigger to the management actions. It is also highly advisable that measures to curb the

worsening of the functionality and durability state of the bridge should be used together when

implementing structural monitoring, such that the bridge can avoid suddenly falling into

acritical condition.

Note that, at the design and implementing stage of remedial measures to the bridge, the road

administrator will comprehensively reexamine the specific details and methods considered

during the periodic inspection.

(4) In periodic inspections, a relevant integrity diagnosis classification shall be determined for

each facility as required in the ministry notification.

Every bridge comprises three primary structural parts from the viewpoint of the load paths and

different primary roles in the load-carrying mechanism, “superstructure,” “substructure,” and

“connection between superstructure and substructure,” where their functional roles and

definitions are given in the Specifications for Road bridges, 2017. Accordingly, when

considering the condition of the entire bridge under anticipated situations, it is reasonable first

to assess if each structural component can retain the load-carrying function to fulfill its role

under those conditions, such that the probable load-carrying function state of all components

can be incorporated into the evaluation for the condition as the entire bridge. Furthermore, in

recording and storing the bridge inspection result, it is desirable to record not only the

evaluation result of the whole bridge but also the load-carrying function and function fulfillment

assessment of those primary structural components, because the assessment result of the load-

carrying performance of a road bridge serves as one of the primary bases for determining the

integrity diagnosis classification and also will be referred in future maintenance and

management.

The distinction between the superstructure, substructure, and the superstructure-substructure

connection is based on the concept that a bridge must consist of role-wise structural components,

regardless of bridge types, structural forms, or design concepts. Sometimes, one structural

member serves multiple roles, making it difficult to identify which one of the primary structural

components the structural member exactly contributes role-wise in inspection, depending on

the type of the bridge and the structural member. However, when making a general assessment

of the load-bearing performance of the bridge to obtain the overall integrity diagnosis

classification, it is usually unnecessary to strictly identify or clarify the roles of the structural

member.

Note that the statutory periodic inspection does not necessarily require structural analyses or

calculations. It also does not basically require detailed surveys or measurements or the use of

advanced investigation technologies. It requires fundamental observations commonly

accepted in inspection practice, and such observations are enough to provide information to

conduct the present and future performance evaluations for one of the primary bases in

determining the integrity diagnosis classification. Accordingly, the classification of structural

members and parts into one of the structural components of role, i.e., superstructure, substructure,

and superstructure-substructure connection, and the technical level and reliability

in the performance evaluation of the probable state of the identified components under

anticipated situations until next inspection are regarded sufficient to be based on the subjective

judgment by a person with enough knowledge and skill to fulfill these processes of the statutory

periodic inspections and the person's close visual observations. However, the final judgment

of these technical aspects and the requirement of the inspector's skill and knowledge rests with

the road administrator.

When evaluating the structural role sufficiency of the primary structural components under

anticipated situations until the next inspection, it is advisable to involve anticipated situations

with load combinations that are unlikely under normal use but not impossible. These include

excessive live load situations, such as simultaneous multiple heavy vehicles loading,

earthquakes as large enough as the road administrator should conduct post-event patrols or

emergency inspections, and rare flooding that could pose a risk to the bridge, which is best to

anticipate based on its location. It is also advisable to consider other situations as needed,

given the road bridge’s state and structural conditions. For example, typhoons or other strong

winds would be considered, depending on the bridge type and structural characteristics.

The inspector’s evaluation of the probable state under those anticipated situations until the next

inspection should account for structural safety, driving safety, and the risk of damage to third

parties from the perspective of road functionality. Accordingly, the inspector should infer the

bridge state to classify it into the following scale of A to C, which will be referred to by the

bridge administrator in determining the integrity diagnosis classification:

Note that these inferences and evaluations are allowed to be based on the information obtained. A critical state herein refers to a condition where safe passage cannot be ensured without road

closures or significant load restrictions. For example, this could include the state where,

although it does not result in a complete bridge collapse, there is severe damage deterioration

at the support points or main girders, rendering the bridge impassable. It could also include

situations where the substructure is damaged or destabilized, making it unable to support the

superstructure safely. Besides the condition from the perspective of the bridge's structural

safety, it also includes conditions from the drivability standpoint, such as significant bumps or

road surface subsidence that make passage difficult. The specific condition that is anticipated

and the extent to which the bridge or roadway functions are at risk of being compromised at

that time depends on the conditions of the bridge thereof and the surrounding ground to be

evaluated together with the bridge. Accordingly, it should be determined for each bridge

individually.

The classification in A to C represents a rough evaluation of the probable state in response to

the anticipated situations. It is the subject of the condition of the bridge thereof. Assuming the

state where there is a risk that corrosion fragments, concrete pieces, or any attachments fall

down from the bridge, posing a risk of harming the third party on/under the bridge, prompt

measures are usually implemented as soon as such distress is observed during the inspection,

and it is not necessary to consider the classification in A to C as part of the result of the

inspection. Inversely, in cases with a potential for severe third-party damage to occur due to

such causes but no measures are taken to address them during the inspection, incorporate it into

the classification in A to C if necessary.

In addition, when the road administrator determines the integrity diagnosis classification, it may

be reasonable to consider the need to take some measures from a mid to long-term maintenance

plan perspective. This includes the anticipated changes in condition and performance until

the next periodic inspection and considerations on whether the implementation of preventive

maintenance measures should be timely. Therefore, it is vital to pay special attention to factors

such as fatigue, chloride ingress and salt damage, alkali-silica reaction, deterioration of

anticorrosive function, and scouring, as well as earlier maintenance histories in the statutory

periodic inspection, which are valuable to consider the need of preventive maintenance, such

that the road administrator can conduct the integrity diagnosis classification relevantly

following their mid to long-term bridge preservation policy. Additionally, it is advisable to

keep records of these factors and the relationship between them and the road administrator’s

integrity diagnosis classification because they often significantly impact the road

administrator’s decision and are valuable.

(1) The results of periodic inspections should be recorded in a form that can cover the

information considered necessary to utilize in appropriate maintenance and management,

including responses in the event of in-service damage as follows:

(2) It is desirable to record the measures considered in Section 5 and their technical

backgrounds that involve the views on the inferred functional states of the superstructure,

substructure, and super-substructure connection under the anticipated situations, the

necessity of preventive maintenance, and the potential for third-party damage under the

anticipated situations.

The results of periodic inspections are fundamental information used as a reference for planning

maintenance and repair, etc., and should be recorded and accumulated appropriately.

There are no legal requirements regarding the form, content, or items of records related to

periodic inspections. Recording information that the road administrator deems necessary for

proper maintenance and management in an appropriate manner is sufficient.

Given the law, it is advisable to include observations on the state of the road bridge regarding

its structural safety under anticipated situations, the necessity for preventive maintenance, and

the potential for third-party damage. These observations are considered essential information

for appropriately planning maintenance and repairs. Additionally, it is beneficial to include

observations on the overall need for measures until the next periodic road bridge inspection.

(See Form 1, Form 2 and Form 3)

At this time, as recommended in "5. Determination of integrity diagnosis classification (4),"

it is desirable to retain the estimated results of the expected condition of each part of the bridge,

including the superstructure, substructure, and connection between superstructure and

substructure, which bear the load carrying performance of the bridge. This should clarify the

relationship between the technical evaluation of the bridge's condition and the main reasons

influencing the determination of the integrity diagnosis classification. Additionally,

evaluating the fail-safes and expansion joints is often considered to influence the judgment of

the necessity of measures, and recording these evaluations is also regarded as adequate for

appropriate maintenance. For example, fail-safes are evaluated from the technical viewpoint

of performing expected functions when they would be functional, and expansion joints are

evaluated from the technical viewpoint of providing safe traffic, given various vehicles passing

over.

Moreover, insights into how the results of the various evaluations conducted to determine the

“integrity diagnosis classification,” as mentioned above, ultimately led to the final decision

are necessary for implementing appropriate measures. Therefore, it is considered essential

to record these insights as observations.

Other than these, it is not precluded to enhance records as necessary, in addition to following

the provisions indicated in these guidelines for proper maintenance. It is advisable to

consider the selection of record items and methods by expressly assuming the purpose of use.

Furthermore, as stipulated in the regulations related to maintenance (Article 4-5-6 of the

Order for Enforcement of the Road Act), the details of any measures taken must be recorded.

The results of periodic inspections are fundamental information used as a reference for

planning maintenance and repair, etc., and should be recorded and accumulated appropriately.

There are no prescribed formats, contents, or items for recording measures. The road

administrator should appropriately determine these.

It is advisable to refer to the explanation in Section 5 regarding the content that should be

recorded. This form is intended to record not only the facility specifications but also the integrity

diagnosis classification of road bridges and the results of the technical evaluations regarding

the potential conditions that may arise under the anticipated situations. It is intended to be

recorded as follows.

Select and record the condition of the bridge and superstructure, etc., for the anticipated

situations from the following options: A, B, or C. Additionally, fail-safes' functionality must not be considered when conducting technical

evaluations of the condition in response to earthquake impacts.

For other aspects (fail-safes), if a bridge is equipped with fail-safes intended to function

during earthquakes, the evaluation should focus on these devices and assess whether they can

adequately perform their intended functions, assuming the bridge relies on them during an

earthquake. In other words, in this case, any form of deterioration corresponds to a state

where the fail-safes cannot perform their expected functions, and a critical state corresponds

to a state where the fail-safes are destroyed or lose their function without being able to

perform their intended functions.

For other aspects (expansion joints), evaluations should be conducted to ensure the travel

performance of the expansion joints in response to "live loads." Additionally, evaluation of the

expansion joints' structural safety will generally reveal conditions that may ultimately

compromise travel safety. Therefore, evaluations should be conducted to ensure travel safety

by considering these.

Record the photo numbers of the applicable Form 2. In the parentheses ( ) in “Other,” record the situations anticipated to occur other than live

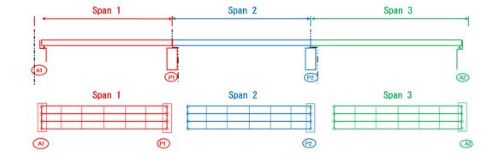

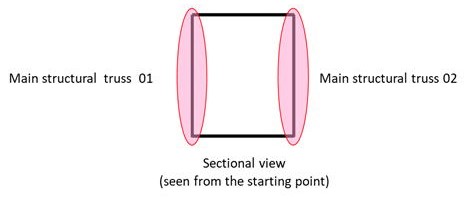

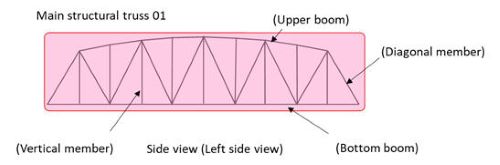

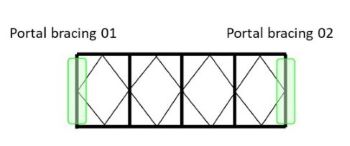

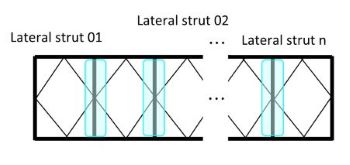

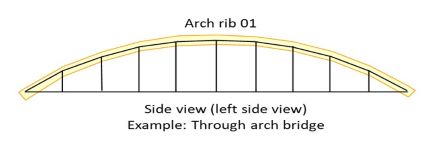

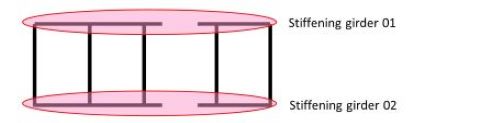

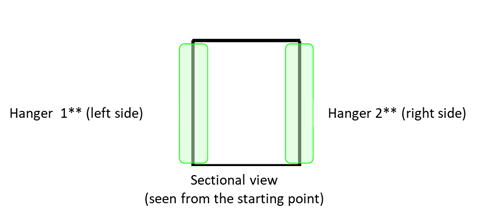

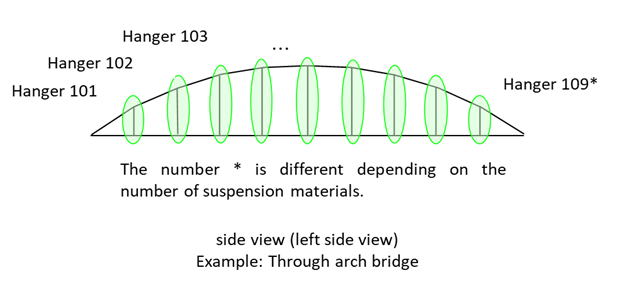

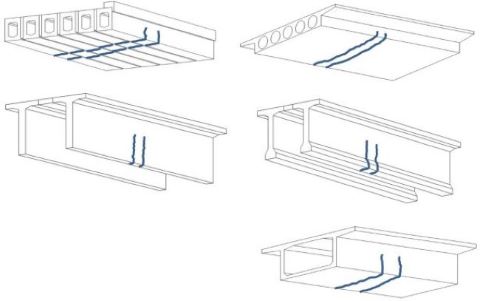

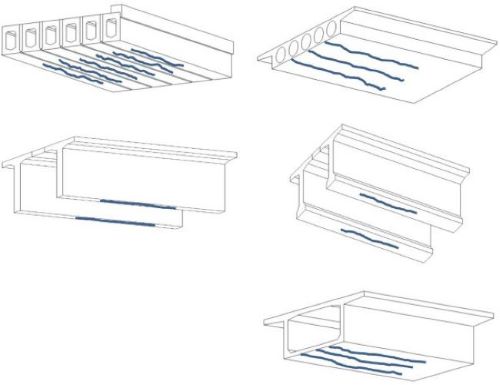

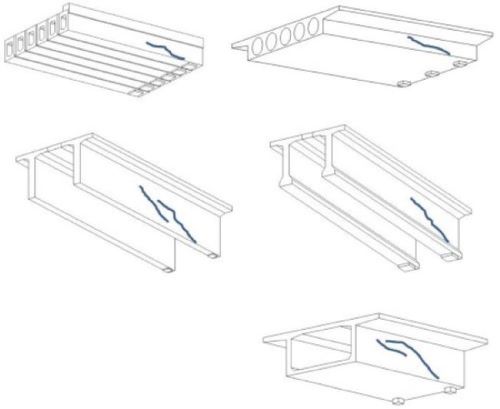

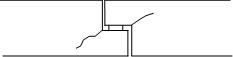

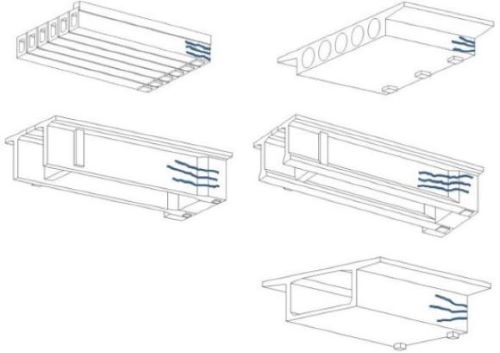

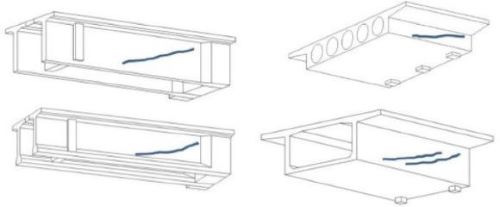

loads and earthquakes, such as strong winds. Here are examples of general interpretations of different structural parts with different roles for

the main structural type, i.e., the superstructure, the substructure, and the connection between

the superstructure and substructure.

It should be noted that even if the bridge type is the same, the specific roles played by different

parts of the bridge structure are not necessarily the same.

Therefore, periodic inspections should determine which structural parts should be treated as

superstructure, substructure, and connection between superstructure and substructure. This will

reflect how the bridge's components are to be viewed in evaluating the bridge's performance

and condition, which is done to determine the integrity diagnosis classification. For the next

periodic inspection and future maintenance, it is advisable to record, as necessary, how the

components were perceived.

This form is used to record the condition of the road bridge as determined at the time of

inspection, which serves as the basis for the integrity diagnosis classification and technical

evaluation in Form 1. It is necessary to retain the required number of photographs with the

quality and content needed as helpful information for future verification and other uses. For

example, even in cases where “A: The likelihood of damage or irregularity to the dysfunction

of the bridge is low.” this form allows you to record not only the conditions that serve as the

basis for this evaluation and the conditions of the members for which failures are considered

possible but also the reasons for any expected deterioration. It is intended to be recorded as

follows.

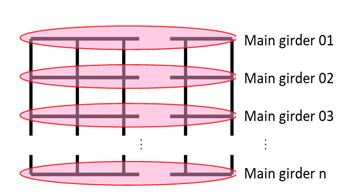

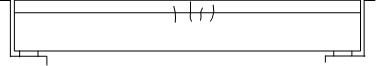

Designate the different structural components of distinct roles: “superstructure,” “substructure,”

“super-substructure connection,” “other (fail-safe),” “other (expansion joints),” and “others.”

Select from “live load,” “earthquake,” “heavy rain/flood,” and “others.”

In the case of “others,” record the applicable situation, such as “strong winds.”

Record the condition of the whole bridge and its components inferred for the anticipated

situations by selecting from the following categories: A, B, and C:

Record the condition of the road bridge components, which served as the basis for the integrity

diagnosis classification and technical evaluation results in Form 1, with photographs taken at

the time of inspection. Fill in the photo number and member number, if any.

For the photographs, describe technical perspectives on how satisfied the component plays their

given mechanical roles, as necessary. Referring to "6. Functional requirement of

components," record the existence or absence of a decline in the given function and the

possibility of a loss of the given function as the background information on the technical

performance evaluation, such as

Note that, for "others" components, it is not necessary to follow the bullet points above but to

clarify the technical aspects considered when describing the background views for the

evaluation.

In estimating whether the superstructure, substructure, and connection between superstructure

and substructure can each fulfill their required roles, it is necessary to assess whether they are

in a condition that allows them to perform the functions needed for those roles. The

component's ability to sufficiently perform their given functions should be estimated by

inferring whether the components can carry and transmit loads under the anticipated situations.

The function of individual components can be classified as follows:

1. Superstructure ⅰ. The function of directly supporting the loads acting on the road surface from passing

vehicles and other sources ⅱ. The function of carrying vertical and horizontal loads acting on the superstructure and

transmitting them to the super-substructure connection ⅲ. The function of facilitating the smooth support and transmission of loads when the

main girder or other components transfer loads acting on the superstructure to the

connection between the superstructure and the substructure 2. Super-substructure connection ⅳ. The function of supporting the loads from the superstructure and transmitting them to

the substructure ⅴ. The function of providing the necessary geometric boundary conditions for the

superstructure and substructure to perform their functions 3. Substructure

ⅵ. The function of directly supporting loads from the connection between superstructure

and substructure, transmitting them to the foundation and surrounding ground, and

maintaining the connection between superstructure and substructure ⅶ. The function of supporting loads from the pier and abutment columns and walls,

transmitting them to the surrounding ground related to the stability of the bridge, and

maintaining the bridge's position at the ground level This form is used to record the necessity of preventive maintenance considered in determining

the integrity diagnosis classification as well as the assumptions and observations underlying the

integrity diagnosis classification in Form 1. It is intended to be recorded as follows. During periodic inspections, the integrity diagnosis classification is primarily based on the

potential conditions the structure might fall into until the next inspection. In general, for road bridges, the condition of the bridge is unlikely to change significantly over

about five years due to long-term effects such as environmental actions or fatigue phenomena

that are evaluated in terms of durability performance. Therefore, it is generally sufficient to

base the integrity diagnosis classification primarily on the condition observed at the time of the

inspection. However, for example, in cases where there is a higher potential for rapid fatigue damage

progression, such as structural details with significantly poor fatigue durability or those

subjected to severe heavy traffic, or where there is a particular concern about the potential for

steel corrosion due to salt exposure and its rapid progression, or where it is determined that

deterioration due to alkali-silica reaction is progressing, it is necessary to consider the

possibility of rapid changes in condition due to these effects before the next periodic inspection

in evaluating the load-carrying performance of the whole bridge and its structural components. Inversely, this kind of bridge condition can be avoided when preventive maintenance with

appropriate measures is taken at the right time, while these types of deterioration often progress

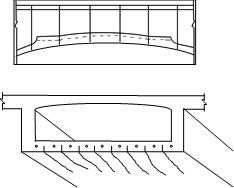

steadily. Similarly, scouring is a phenomenon where abrupt changes in conditions can occur during

events such as floods. In cases where such risks exist, it is essential to consider preventive

measures or verify the condition after floods as necessary. Based on these considerations, Form 3 allows for recording “designated deterioration types and

phenomena” to contribute to rational maintenance based on past knowledge, for which it is

considered essential to know whether these conditions are met to conduct effective maintenance. Additionally, close visual inspection is the primary approach for periodic inspections. While

the extent of investigation and measurement details to understand the existence of these

deterioration types and phenomena during the periodic inspection depends on the judgment of

the road administrator, the latest evaluation reflecting the observed facts should be recorded. Examples of deterioration and phenomena to be designated are shown below: While understanding the condition is fundamentally based on close visual inspection of external

features, sounding, and palpation, there are parts and members whose condition cannot be

evaluated through close visual inspection. Since the accuracy of understanding the condition

affects the performance evaluation, if there are parts and members whose condition cannot be

evaluated through close visual inspection, this should be recorded as a premise for the integrity

diagnosis classification. Additionally, when using inspection support technologies or non-destructive inspection

technologies, record the structural parts and members such technologies are utilized for and

document information about the technology used to enable future verification.

When evaluating the condition of road bridges, it is standard practice to remove flaking,

detached fragments or peeled sections and corroded fragments that may pose a risk to third

parties, or to improve the attachment condition of accessories as an emergency measure.

Therefore, record whether these actions have been carried out. Additionally, considering

whether emergency measures have been implemented, also record whether further actions are

necessary as part of the observations on the condition of the road bridge regarding the potential

for third-party damage until the next periodic inspection. At this time, if there are any

considerations such as the implementation of measures to prevent the progression of

deterioration, record these as well, including the assumptions and conditions that were taken

into account for the observations. Additionally, record this information in the section for components such as the superstructure

where the relevant accessories are installed. The findings and supplemental comments should include technical opinions that are

significantly related to the determination of the “integrity diagnosis classification” in such a

way that their relevance to the approach to the measures can be understood. In general, the report will include the following information, as well as a technical evaluation

of the need for these measures and an overall finding on the measures to be taken until the next

periodic inspection. Additionally, if the integrity diagnosis classification was based on certain assumptions or

conditions, such as the implementation of regulations or monitoring, those assumptions and

conditions should also be recorded. As a comprehensive understanding, it is particularly important that, based on the findings for

specific events in Forms 1, 2, and 3, a rationale, such as a technical opinion, is provided on how

the concept of measures reflected in the determination of the “integrity diagnosis classification”

is derived as appropriate from the results of each of those conditions and evaluations. The following are the items that should generally be included in the findings and comprehensive

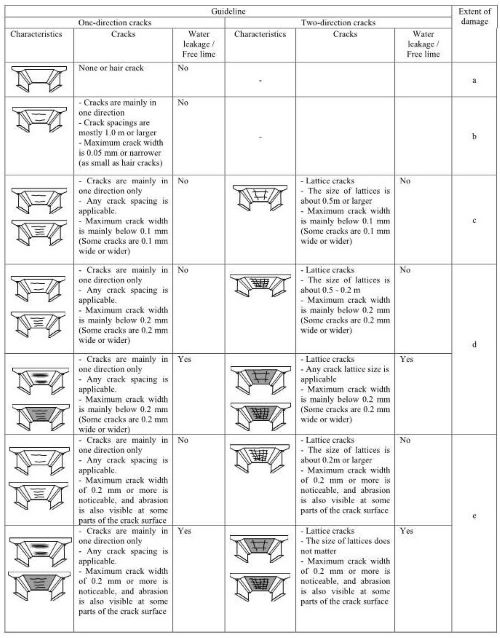

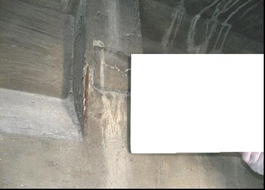

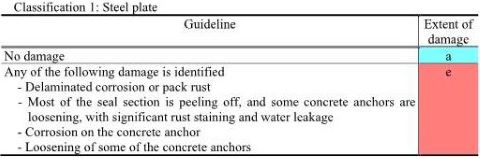

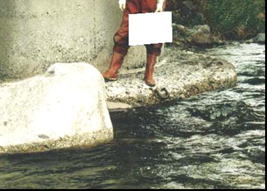

comments. This guideline provides standard recording protocols to be used when objective recording is conducted for the statistical analysis of inspection data. This guideline is designed to make such recording as minimum as possible, on the basis of knowledge on the deterioration tendency of road bridges acquired from earlier periodic inspections. Note that it is bridge owners' discretion for the recording protocols and items depending on their needs. Major members shall be selected as appropriate from structural types. Members to be selected are as follows: (1) For steel bridges 1) Steel slab girder bridge * "Road surface" will be selected for all structural types, even if not specified. 2) Steel box girder bridge 3) Steel truss bridge 4) Through arch bridg 5) Deck arch bridge 6) Rigid-frame bridge 7) Cable-stayed bridge 8) Suspension bridge (2) For concrete bridges 1) PC slab bridge * "Road surface" will be selected for all structural types, even if not specified. 2) PC T-girder bridge 3) PC box girder bridge Table-3.1 lists the types and extent of damage. For the purpose of classification, categories a-e are provided for each type of damage dealt with in this guideline. The extent of damage appearance is objective, not subjective. The extent of damage is defined with numerical and quantitative indicators wherever possible. Some damage types are covered by only ‘a’ and ‘e’, only ‘a’, ‘c’ and ‘e’, or ‘a’, ‘c’, ‘d’ and ‘e’. Some damage types are classified using a combination of two parameters. For example, corrosion is evaluated in terms of the decrease in plate thickness and the extent of the corroded area, and concrete cracking is measured by a combination of crack width and crack density. Photographic examples are also given to avoid confusion in classifying the extent of damage. Data-recording personnel are not allowed to incorporate their views on the maintenance and repair urgency into the classifications of the extent of damage; they must strictly match the damage appearance with the definitions and photographic examples. Table 3.1 Types of damage and classifications of damage extents Types of damage Classifications of the extent of damage Corrosion a—e Cracking a, e Bolt loss a, e Rupture a, e Deterioration of corrosion protection a—e Cracking, water seepage, efflorescence a—e Exposed rebar a, e Deck slab punching failure a, e Deck slab crack a—e Distress in the tendon anchorage zone a, e Road surface crack, rutting, roughness etc. a, e Bearing malfunctioning a, e Damage to repair and reinforcement materials a, e Subsidence, dislocation, tilting a, e Scouring a, e (1) Corrosion 1) Classifications of the extent of damage Guideline Extent of damage Existence of damage Corrosion depth Corrosion area No - - a Yes Decrease in plate thickness is negligible or rust has developed only on the plate surface Rust areas are not widespread but exist only locally b Rust or several ruts areas have spread over the data recording segment c Decrease in plate sickness is notable or the swelling of rust is visible Rust areas are not widespread but exist only locally d Rust or several ruts areas have spread over the data recording segment e [Examples] The extent of damage b The extent of damage c Some parts of the main girder have superficial rust The lower flange has superficial rust all over it The extent of damage d The extent of damage e The end part of the main girder has rust which is local but with the reduction of plate thickness There is significant rusting throughout the main girder with the reduction of plate thickness (2) Fissure 1) Classifications of the extent of amage Guideline Extent of damage None Paint crack exists but is not related to the crack in the plate or at the welding connection. (Short paint coating crack without rust) a Clear cracking Identified paint crack is likely to be associated with the existence in the crack in the plate or at the welding connection (linear cracks, some rust) e [Examples] The extent of damage a The extent of damage a Minute or very short crack Paint coating crack that is assumed not to be associated with plate cracking The extent of damage e The extent of damage e Cracking is linear and obvious Paint coating crack that is likely to be caused by the crack in the plate or at the welding connection The extent of damage e The extent of damage e Crack in the Gerber hinge connection Crack in the bridge girder section with reduced depth at the bridge support (3) Bolt fallout 1) Classifications of damage extents Guideline Extent of damage No damage a Some bolts are lost (regardless of the number of the fallen bolts) e [Examples] Damage extent e Damage extent e A bolt has fallen off Bolts have broken and fallen off (4) Rupture 1) Classifications of damage extents Guideline Extent of damage No damage a Ruptured (If the member is not split apart, the distress may be identified as cracking, not rupture.) e [Examples] Damage extent e Damage extent e A gusset plate in the sway bracing is A gusset plate in the lateral bracing is ruptured (5) Deterioration of the anticorrosive function 1) Classifications of damage extents Classification 1: Paint coating Guideline Extent of damage No damage a Discoloration or localized bubbling develops in top layer c The coat layers are partially peeling off, and the primer is exposed d The paint coating system deteriorates over a wide area with are some rust spots e [Examples] Damage extent c The finish coat is discolored Localized swelling is developed Damage extent d Damage extent d The top and intermediate coats are partially peeling off and the primer is exposed The top and intermediate coats are partially peeling off and the primer is exposed Damage extent e Damage extent e Rust spots over a wide area Rust spots spreads over a wide area Classification 2: Galvanization protection or, metal spraying Guideline Extent of damage No damage a The coating deteriorates locally with some rust spots. c The coating deteriorates over a wide area, with rust spots e [Examples] Damage extent c Damage extent c The coating film deteriorates locally, and rust develops on the base material The coating film deteriorates locally, and rust develops on the base material Damage extent e Damage extent e The coating deteriorates over a wide area, with some rust spots The coating deteriorates over a wide area, with many rust spots throughout the entire area Classification 3: Weathering steel Guideline Extent of damage No damage (Uniformly distributed, dark brown fine rust grains can be considered as fully developed protective rust) (Yellow, red , orange, or light brown rust can be considered in the early development stage to the protective rust) a No damage. However, protective rust has not started being formed yet b Coarse grained or granular texture rust with 1 to 5 mm in diameter/size c Flakes with 5-25 mm in size d Delamination e Examples. Damage extent b Damage extent b No protective rust has developed No protective rust has developed Damage extent c Damage extent c Rust is about 3 mm in size and coarse-grained Rust is about 3 mm in size and coarse-grained Damage extent d Damage extent d Flakes with 5 to 15 mm in size Flakes with approximately 6 mm in size Damage extent e Damage extent e Delamination Delamination (6) Cracking, water seepage, and efflorescence 1) Classifications of damage extents Guideline Extent of damage Existence of cracks Crack width Water leakage and free lime No None or hair cracks No water seepage or efflorescence a Yes Less than 0.2 mm No water seepage or efflorescence b 0.2 mm or larger No water seepage or efflorescence c Any width Water seepage through a crack; no rust stain or efflorescence visible d Efflorescence; no rust stain visible d Water seepage involving notable mud-like stain or rust stain e 2) Crack patterns Crack patterns shall be categorized according to the tables below, and corresponding pattern numbers shall be recorded. a) Superstructure (Common definitions for both PC and RC members) Location Crack pattern Span center (1) Transverse cracks on the bottom surface or vertical crack on the side surface/web of the main girder (2) Longitudinal cracks on the bottom surface of the main girder 1/4 point of span (3) Transverse cracks on the bottom surface or vertical crack on the side surface/web of the main girder Support section (4) Diagonal cracks in the web at support (5) Transverse cracks on the bottom surface or vertical crack on the side surface/web of the girder at support (6) Diagonal cracks on the side of the girder at support (7) Cracks in in-span or Gerber hinge section or dapped-end beam (8) Vertical cracks in the upper part of continuous spans at intermediate support Others (9) Map cracking (10) Cracks occurring vertically at regular intervals in the web of the girder (11) Horizontal cracks near the junction between the web and the upper flange (12) Cracks in 45-extent diagonal direction occurring all over the girder 1/4 point of span, or the support section (21) Longitudinal cracks on the bottom or side surface of the girder (excluding those that fall under (19)) (22) Cracks on the upper flange Entire span (23) Horizontal cracks developed throughout the web Cross beams (24) Cracks on the cross beam (1) Span center, transverse cracks on the bottom surface or vertical crack on the side surface/web of the main girder (2) Span center, longitudinal cracks on the bottom surface of the main girder (3) 1/4 point of span, vertical or diagonal cracks on the bottom or side surface of the main girder in the direction perpendicular to that of the girder (4) Support section, diagonal cracks in the web at support (5) Support section, transverse cracks on the bottom surface or vertical crack on the side surface/web of the girder at support (6) Support section, diagonal cracks on the side of the girder at support (7) Cracks in in-span or Gerber hinge section or dapped-end beam (8) Support section, vertical cracks in the upper part of continuous spans at intermediate support (9) Map cracking (10) Cracks occurring vertically at regular intervals in the web of the girder (11) Horizontal cracks near the junction between the web and the upper flange (12) Cracks in 45-extent diagonal direction occurring all over the girder (21) 1/4 point of span, or the support section, longitudinal cracks on the bottom or side surface of the girder (excluding those that fall under (19)) (22) 1/4 point of span, or the support section, cracks on the upper flange (23) Entire span, horizontal cracks developed throughout the web (24) Cracks on the cross beam Location Crack pattern Span center (13) Cracks along tendons in the lower flange of the girder with variable cross section (18) Cracks in the vicinity of the upper flange of the main girder 1/4 point of span (14) Cracks along tendons around the inflection point close to a intermediate support of the PC continuous girder (15) Cracks perpendicular to tendons around the inflection point close to the intermediate support of the PC continuous girder Support section (19) Horizontal cracks on the web of the main girder (25) Cracks in the connected cross beam section (RC structure section) Others (16) Cracks around the anchorage zone or the deflection point of tendons (17) Cracks in an area where tendons are concentrated (20) Cracks along the sheath (26) Gaps or separation at the segment connection (27) Cracks in an area with an abrupt change in cross section (13) Span center, cracks along tendons in the lower flange of the girder with variable cross section (14) 1/4 point of span, cracks along tendons around the inflection point close to a intermediate support of the PC continuous girder (15) 1/4 point of span, cracks perpendicular to tendons around the inflection point close to the intermediate support of the PC continuous girder (16) Cracks around the anchorage zone or the deflection point of tendons (a) The vicinity of the anchorage protrusion (b) Back-filled concrete area (17) Cracks in an area where tendons are concentrated (18) Span center, cracks in the vicinity of the upper flange of the main girder (19) Support section, horizontal cracks on the web of the main girder (20) Cracks along the sheath (25) Cracks in the connected cross beam section (RC structure section) (26) Gaps or separation at the segment connection (27) Cracks in an area with an abrupt change in cross section Crack pattern (1) Vertical or diagonal cracking with a constant spacing (2) Cracks perpendicular or diagonal to the construction joint (3) Cracks at the rebar cut-off section (4) Map cracking (5) Diagonal cracking in the seat edge, initiating from the front of the bearing (2) Cracks orthogonal or diagonal to the construction joint (3) Cracks in the vicinity of an area where main reinforcement is reduced (4) Map cracking (6) Cracks in the upper part of a pier-cap cantilever end (7) Vertical cracks on the pier-center line in the pier cap (8) Cracks at the corner of a pier cap-column connection (13) Vertical cracks on the side surface (4) Map cracking (9) Cracks all around the top or base of a column or a corner of a hunch (10) Cracks all around a pillar (11) Cracks all around the pier cap or a hunch (12) Cracks on the bottom of the center span of the pier cap [Ex. Superstructure] Damage extent b Cracks with the width smaller than 0.2 mm Damage extent c Damage extent d Cracks in 0.2 mm wide or wider Cracks with water leakage are identified Damage extent d Damage extent d Cracks with water leakage and efflorescence Cracks with water leakage and efflorescence Damage extent e Cracks with rust rust staining [Ex. Substructure] Damage extent b Cracks with the width smaller than 0.2 mm Damage extent c Damage extent d Cracks in 0.2 mm wide or wider Cracks with water leakage are identified Damage extent d Damage extent d Cracks with water leakage and efflorescence Cracks with efflorescence Damage extent e Cracks with rust staining (7) Exposed rebars 1) Classifications of damage extents Guideline Extent of damage Existence of exposed rebars Spread of exposure and corrosion Extent of corrosion No - - a Yes Limited Unmeasurable section loss Measurable section loss, or significant corrosion volume expansion of reinforcement Wide area Unmeasurable section loss Measurable section loss, or significant corrosion volume expansion of reinforcement e [Examples] Damage extent a Damage extent a Partial rebar exposure Superficial rebar exposure over a wide area Damage extent e Damage extent e Reinforcement corrosion over a wide area Reinforcement corrosion over a wide area (8) Fallout 1) Classifications of damage extents Guideline Extent of damage Not applicable a Full-depth hole in the deck slab after concrete block has fell down out of the concrete deck slab e [Examples] Damage extent a Damage extent a Shall be assessed as "cracked deck slabs", since significant cracks have developed Shall be assessed as "exposed rebars", since rebars are significantly exposed Damage extent e Damage extent e A part of the deck concrete has fell down with a full-depth Concrete block has fell down out of the longitudinal connection (9) Cracked deck slabs 1) Classifications of damage extents [Examples] Damage extent b One-directional cracks prevail (The cracks are marked with chalk) Damage extent c Damage extent c One-directional cracks prevail (The cracks are marked with chalk) Lattice cracks have developed (The cracks are marked with chalk) Damage extent d Damage extent d One-directional cracks with efflorescence Two-directional cracks with efflorescence (The cracks are marked with chalk) Damage extent e Damage extent e Significant one-directional cracks and efflorescence Dense lattice cracks with abrasions and efflorescence (10) Abnormality in the PC anchorage zone 1) Classifications of damage extents Guideline Extent of damage No damage a Damage to the tendon anchorage zone (in any extent) Damaged tendon e [Examples] Damage extent e Damage extent e Rust staining in the anchorage zone Rust staining in the anchorage zone Damage extent e Damage extent e Spalling concrete and the corrosion of the exposed wedges and strand at the anchorage Spalling of the concrete and sticking out of the transverse tendons at the anchor (11) Uneven road surfaces 1) Classifications of damage extents Guideline Extent of damage No damage There are uneven expansion joint of less than 20 mm (not so large as to impair traffic safety for vehicles) a Visible uneven joint about 20 mm or larger (large enough to impair traffic safety for vehicles) e [Examples] Damage extent a Damage extent e Uneven joint between the bridge deck slab and the approach with a difference in level less than 20 mm A difference in level about 20 mm or larger over the expansion joint (12) Impaired bearing function 1) Classifications of damage extents Guideline Extent of damage Damage that may affect the bearing function is none a The function of the bearing is impaired The function of the bearing is severely obstructed e [Examples] Damage extent a Damage extent a A loose anchor bolt is present but the bearing is functioning The bearing seat concrete is damaged but the bearing function is maintained Damage extent a Damage extent e Pack rust is present, but cannot cause a significant bearing dysfunction. Sediment accumulation causes the restriction of the bearing movement Damage extent e Damage extent e The bearing is uplifted The bearing is broken (13) Damaged repair and reinforcement materials 1) Typeof repair and reinforcement materials Repair and reinforcement materials shall be classified as follows. A) Repair and reinforcement materials for concrete members Classification Repair and reinforcement materials 1 Steel plate 2 Fibers 3 Cementituous materials 4 Paint (B) Repair and reinforcement for steel members Classification Repair and reinforcement materials 5 Added cover plates and stiffeners 2) Classifications of damage extents Classification 1: Steel plate [Examples] Damage extent e Damage extent e The entire steel plate is corroded A significant amount of rust staining is visible around the steel plate Classification 2: Fibers Guideline Extent of damage No damage a The reinforcement material is severely damaged or ruptured In addition, a large amount of water leakage or free lime is generated from reinforced concrete members e [Examples] Damage extent e Damage extent e The fiber sheet is noticeably cracked, and water leakage with rust staining is identified The fiber sheet is ruptured Classification 3: Concrete series Guideline Extent of damage No damage a A large amount of water leakage or free lime are generated from reinforced concrete members Or the reinforcement material is severely damaged e [Examples] Damage extent e Damage extent e Significant cracks, water leakage and free lime are identified in the concrete jacketing The concrete jacket is severely damaged Classification 4: Paint Guideline Extent of damage No damage a The paint peeling, and rust staining is identified. Or, a large amount of water leakage and free lime are identified e [Examples] Damage extent e Damage extent e Protective coating peeling is present, and rust fluid is identified Protective coating has noticeable cracks with rust staining Classification 5: Steel plate (cover, etc.) Guideline Extent of damage No damage a Significant damage (corrosion, crack, missing bolts, etc.) is identified in the steel plate (such as a cover) e [Example] Damage extent e Damage extent e 3) Note